Amarbir[CDR-Labs said:

":3h8gi06d]

Sam ,

I Have Two Questions For You ...

First : You Designed And Made A Tool To Spread a Multiplatter Platter And Not Loose Alignment .Is This What You Said .If Yes I Too Have a Few Idea On This Project Myself But i Will Not And Cannot Implement It right Now .I Need Some Time To Complete Old Projects And Settle Down

Secondly : You Cleaned The Platter ,You Know We All Have Had A Variety of discussions on this in jareds forum ,Can you mind sharing how and what you did in this regard .

Third : Did any of you try the gorge screwdriver i suggested ?

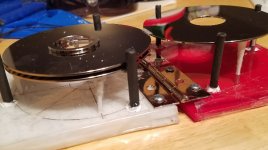

Obviously I did quite a bit of cleanup on the tool after this pic was taken to make it cleanroom-ready. Also, as rough as it looks, the measurements are precise--it took quite a bit of time to get them right.

1) The main idea behind the tool was to keep the platters from moving around while cleaning them. Taped the spacers in place. Platter alignment was kept with metal tape. If I have another case like this I'll figure out a way to put spacers on the outside edges too.

2) I first cleaned the platters with many alcohol swabs that I had dried out. I was pleased with the result of that--platters looked spotless while angling a high-output LED flashlight on them, the same way I typically check platters. Well I had the idea to turn off the light in my cleanroom and check them again and what a stark difference that makes-- Those platters are NOT clean! The main layer of dust was gone but it looked like much of it was ground into the surface. Could barely get any of that off with a dry wipe and only seemed to move the stuff around. Reminded me of why I started using wet wipes after toilet paper (it is NOT clean down there!).

The solution was bunched-up pieces of cleanroom wipe dripping with 99.9% IPA. I had to cut the wipe into smaller pieces and find the right size for the optimal effect. There are some intracies which I'd be happy to help with if anyone is unable to figure it out through experimentation.

3) I have never run across a situation where I've needed to consider torque on the HSA screw. I do however carefully mark original lid alignment before removing it.